A Private Members Association for discriminating luxury leather bag lovers

Free shipping within the United States

A Private Members Association for discriminating luxury leather bag lovers

Free shipping within the United States

You already know what you don’t want. You’ve moved past the point where a recognizable logo adds anything to your life. What you’re looking for now is something harder to find: a bag made with genuine skill, from materials that matter, by someone who understands why those things are connected.

But here’s the problem. ‘Handmade’ has become a marketing term. ‘Luxury’ appears on price tags attached to items that wouldn’t survive a year of actual use. So how do you identify a quality luxury leather handbag—and tell the difference between authentic craftsmanship and convincing imitation?

This is what I look for—and what you can learn to see.

If you want to assess a leather bag quickly, look at its edges. This is where shortcuts become visible and where genuine skill announces itself.

There are three approaches to edge finishing, each with distinct characteristics. Burnished edges are created through friction and heat, compressing the leather fibers into a smooth, sealed surface. The process takes time—sanding through progressively finer grits, applying natural compounds like gum tragacanth or Tokonole, then polishing, often with waxes, until the edge achieves a glass-like finish. On vegetable-tanned leather, a properly burnished edge develops a subtle glow that paint cannot replicate.

Turned edges—where the leather is folded and stitched to hide the raw cut—represent perhaps the most labor-intensive approach. You’ll find this technique on the finest bags because it requires additional material, precise skiving (thinning by blade) to reduce bulk, and considerable hand skill. The result is an edge that feels finished from every angle.

Painted edges can indicate quality or its absence, depending on execution. Done well—multiple thin coats, sanded between applications, built up over time—edge paint creates a durable, refined finish. Done poorly, it peels within months. Run your thumbnail along a painted edge; if you feel roughness or see where layers have separated, that tells you something about how the bag was made.

What to look for: Consistency. Smooth transitions. No visible fibers or rough spots. Edges that feel intentional rather than merely adequate.

Hand stitching in quality leather goods isn’t decorative—it’s structural. The difference between hand-sewn and machine-sewn becomes apparent when you understand what you’re looking at.

Traditional saddle stitching uses two needles working in opposite directions through each hole, creating interlocking stitches. If a single stitch breaks, the thread doesn’t unravel. Machine lockstitch, by contrast, creates a chain that can come undone from a single point of failure.

The visual signature of hand stitching depends on the tools used. French irons (also called pricking irons or chisels) create holes at an angle, so the stitches lean consistently in one direction, producing a distinctive diagonal pattern. Diamond stitching chisels create a different look—equally legitimate, but without that slant. I typically use French irons unless a specific application calls for the diamond pattern. The thread itself matters too—round, cabled linen or polyester thread produces more defined stitches than flat braided alternatives, though it’s far less forgiving of inconsistency.

What to look for: Evenness. Consistent spacing. No loose threads or skipped stitches. And consider this: uneven stitching in hand-sewn goods suggests inexperience, while perfect uniformity might indicate machine work. The goal is controlled consistency with the subtle variations that hand work produces. Every now and then, you’ll find an odd, crooked stitch in my work! Sometimes, the leather has a mind of its own…

The term ‘genuine leather’ on a label tells you almost nothing useful. It’s a legal designation that includes everything from full-grain hides to reconstituted scraps. What matters is understanding what you’re actually touching.

Full-grain leather retains the hide’s natural surface, including its imperfections—healed scars, insect bites, the subtle variations that confirm you’re holding something that was once alive. These characteristics appeal to women who want their bag to tell a story from the start. Corrected-grain leather has been lightly sanded or buffed to create a more uniform surface, then finished with a protective coating. This isn’t a compromise—it’s a deliberate choice that offers different longevity characteristics: greater resistance to scratches and stains, more consistent color over time. I work with luxury corrected leathers from the same distinguished tanneries as my full-grain hides. The choice depends on how you want your bag to age and what your life demands of it.

Dyed-through leather has been colored throughout its thickness, not just on the surface. Examine a cut edge or look at areas of wear—if you see a lighter color beneath the surface, the dye was applied only to the top layer. This matters because surface-dyed leather shows wear more obviously and can look shabby faster than leather that has been properly dyed through.

The tanning method shapes how the leather behaves. Vegetable-tanned leather, processed with natural tannins over weeks or months, develops a patina with use—darkening and developing character in response to how you carry it. Chrome-tanned leather, processed in hours with chemical agents, maintains color stability and offers greater water resistance. Neither is inherently superior; they serve different purposes and appeal to different preferences.

What to look for: A leather that feels substantial without being stiff. Ask about the tannery—reputable makers can tell you exactly where their leather comes from.

Quality hardware is heavy. This is the simplest test, and it’s remarkably reliable. Solid brass or stainless steel components have a weight and temperature that plastic and pot metal cannot imitate. Pick up a zipper pull, a clasp, a D-ring—if it feels insubstantial, it probably is.

For zippers, two names dominate the luxury market. YKK’s EXCELLA line represents the standard for high-end bags—each element individually polished before being attached to the tape, creating a zipper that glides smoothly and won’t degrade with use. Riri, the Swiss manufacturer, produces zippers with equally exacting standards and a distinctive aesthetic that some makers prefer. Both justify their premium over generic alternatives within the first six months of daily use, when cheaper zippers begin to stick, catch, or fail entirely.

Brass hardware will develop a patina over time, changing character as you use the bag. Some makers use protective lacquer to prevent this; others embrace the aging process. Nickel and palladium finishes offer more stability for those who prefer consistency. What matters is that the choice was intentional and the components are solid throughout—not plated over base metal that will eventually show through.

What to look for: Weight. Smooth operation. Look at how hardware is attached—are the stitches reinforced? Do attachment points feel solid and secure?

The inside of a bag reveals what the maker thought you wouldn’t notice. A quality lining isn’t just about aesthetics—it protects the leather’s flesh side, adds structure, enables interior pockets or compartments without visible external stitching, and transforms the daily experience of using the bag.

Suede and leather linings represent the highest standard, adding both durability and a tactile pleasure that fabric cannot match. Quality fabric linings—cotton twill, linen, silk—indicate attention to the complete experience. Synthetic linings can serve adequately but rarely age well.

Look at how the lining is attached. Are seams clean and straight? Are pockets constructed with the same care as the exterior? Can you see any exposed edges, loose threads, or shortcuts? The interior is where production-line bags reveal their compromises.

What to look for: Open the bag in good light. Run your hand along the interior. Notice whether the same standard of finishing applies inside as outside.

A luxury handbag should anticipate how you’ll actually use it. This means reinforcement at stress points—where straps attach, where the bag sits when set down, where corners take the most wear.

Test the straps. Pull them away from the bag body. Quality construction uses multiple rows of stitching, sometimes with hidden rivets, and often with leather reinforcement layers at attachment points. Straps should feel secure, not like they’re asking the stitching to do more work than it was designed for.

If the bag is meant to stand on its own, look for metal feet protecting the base. Examine the corners—are they rounded and reinforced, or sharp angles that will show wear immediately? A well-designed bag accounts for these realities rather than pretending they don’t exist.

The overall silhouette matters too. Quality bags maintain their shape. They don’t slouch awkwardly when empty or bulge strangely when full. This comes from internal structure—stiffening materials, careful attention to how the leather’s weight distributes, understanding how the bag will move with you through a day.

Beyond the functional requirements, genuine craftsmanship often reveals itself in dimensional details—places where the maker chose to add complexity that serves no purpose except beauty and the demonstration of skill.

Raised elements—a filled handle that sits comfortably in your palm, quilting that creates depth, a shaped gusset—require additional time and material. They’re present because someone decided the bag deserved them. A decorative crease line running parallel to edges isn’t structurally necessary, but it indicates a maker who understands that genuine luxury exists in these considered additions.

Consider too the overall proportion. Does the bag feel balanced? Do the elements relate to each other in a way that seems intentional rather than arbitrary? This is harder to articulate than examining a stitch, but it’s immediately apparent when you hold something that was designed rather than merely assembled. You’ll know!

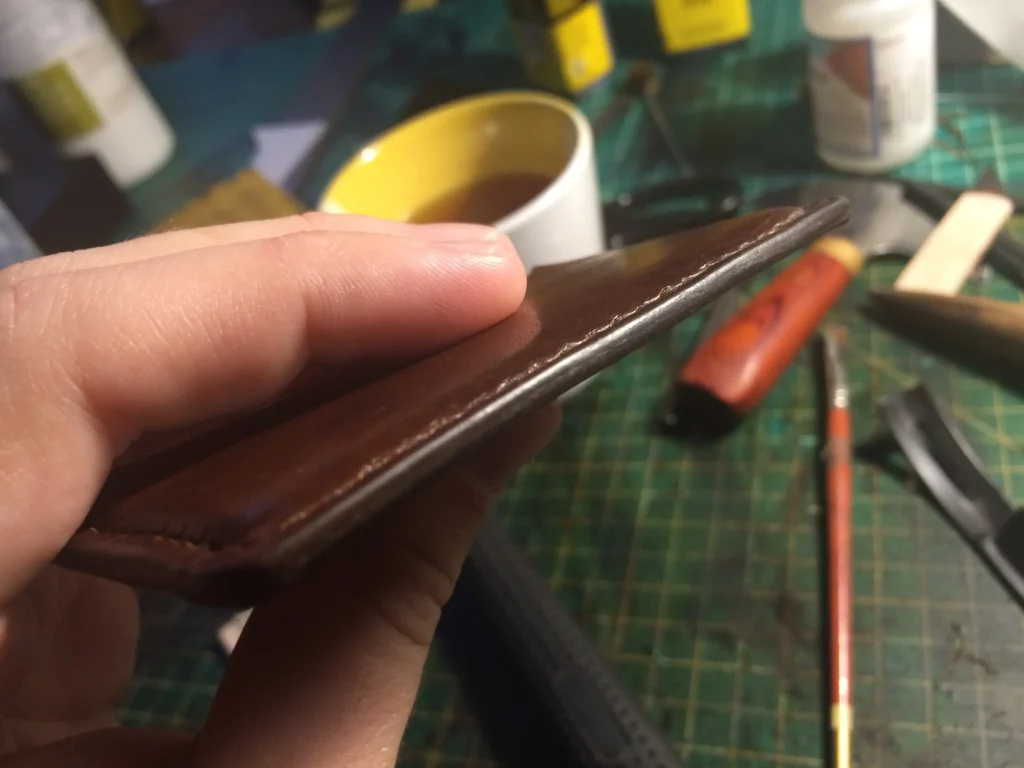

One mark of refined leather goods is slim edges—areas where multiple layers of leather meet without creating unnecessary bulk. This requires skiving (thinning the leather at edges before joining), careful material selection, and an understanding of how thickness affects both appearance and function.

A wallet that resembles a sandwich, a bag with edges that look overstuffed—these indicate either inappropriate material choices or insufficient preparation. The finest leather goods feel substantial without feeling thick. They close cleanly, lay flat appropriately, and maintain their profile over years of use.

What to look for: Edges that feel refined rather than bulky. Closures that meet without straining. An overall impression of precision rather than tolerance.

Most people will never look this closely at a leather bag. They’ll assess the logo, the price, perhaps the color—and move on. That’s fine. Recognition has never been the point for women who choose authentic craftsmanship over manufactured status.

What you’re looking for when you examine edges and stitching and hardware isn’t a checklist to complete. It’s evidence of a conversation between maker and material—choices made thoughtfully, executed with skill, intended to serve you for years. That conversation either happened or it didn’t. Once you know how to listen for it, you’ll hear the difference immediately.

The goal isn’t to become an expert in leatherworking. It’s to become someone who can recognize expertise when she sees it—and who values that recognition as a private understanding between herself and the thing she carries.